A customer in the automotive industry needed to achieve a specific thickness for an essential component of a product through the anodizing process.

Requirement

The objective was to ensure an oxidation thickness between 2 and 5 µ inside a die-cast aluminum tube, ensuring precision and uniformity while meeting the technical and quality requirements specified by the customer.

Developed solution

Alticolor developed an innovative frame that guarantees the presence of an anode inside the tube. This solution increases the wear resistance of parts dedicated to hydraulic coupling.

Validation Tests

To verify process compliance, two tests were conducted at an accredited laboratory:

Salt Spray Corrosion Test

Conducted in accordance with DIN EN ISO 9227.

The test evaluated the tube's resistance to oxidation and corrosion under severe environmental conditions.

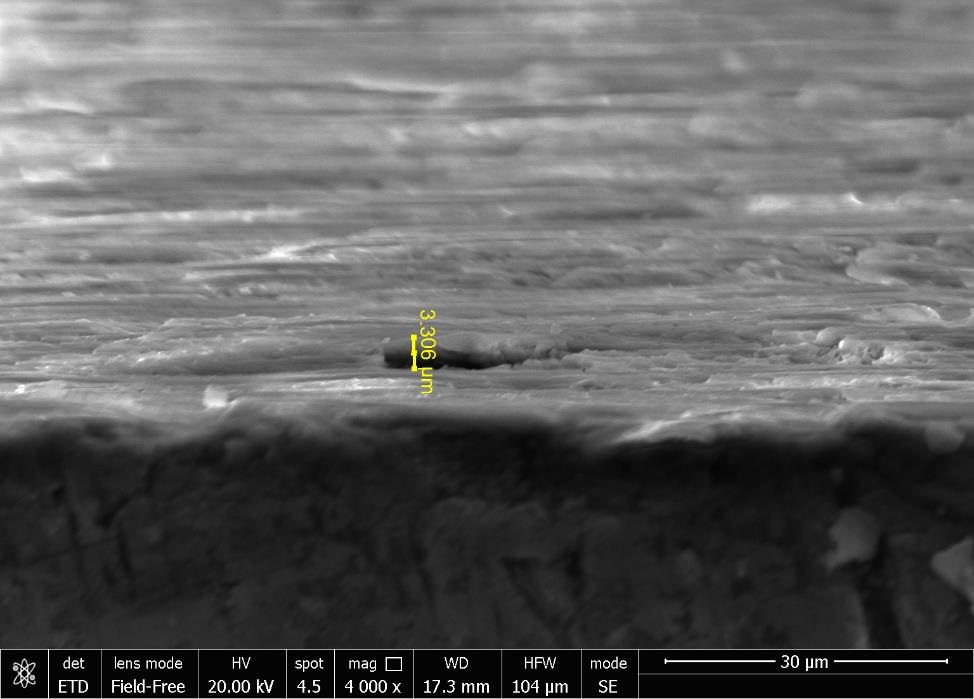

Oxidation Thickness Measurement

Performed according to DIN EN ISO 2360: the test measured the oxide thickness obtained inside the tube.

Results

Both tests yielded positive results, confirming compliance with the required standards. Specifically, the oxidation thickness measurements inside the tube showed values of 2.293 µ and 3.306 µ. These results fall perfectly within the range required by the customer, demonstrating the effectiveness of the process developed by Alticolor.

The success of this project allowed Alticolor to showcase the strength of its in-house Research and Development department, implementing a new solution that brought the component to a new level of performance.

Alticolor offers a wide range of treatments tailored to companies operating in the automotive sector. Do you need a special treatment for components used in this field?