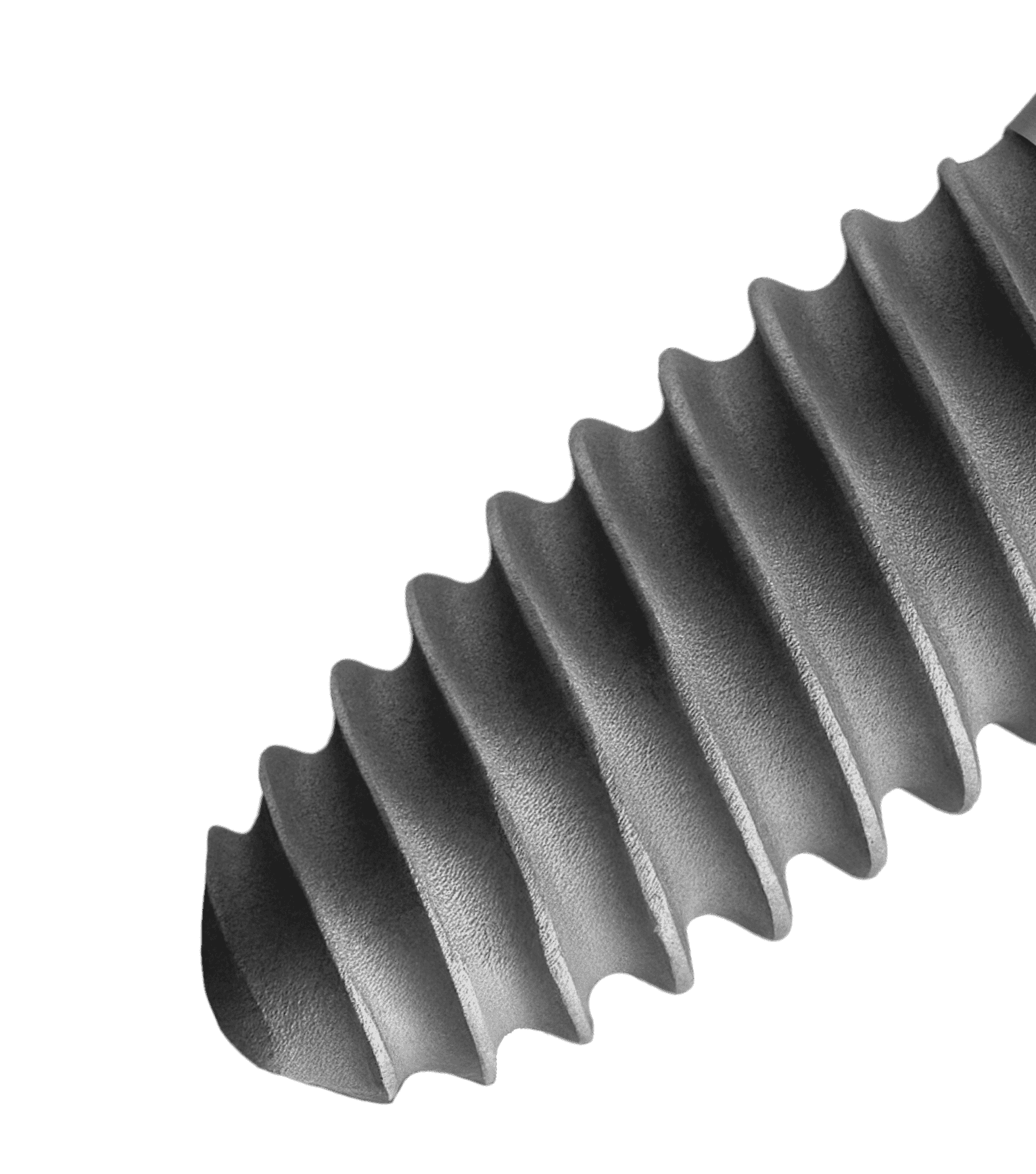

The technique of double acid etching on titanium involves creating macro roughness followed by etching with acid, which puts micro roughness over the prior macro roughness.

The production cycles involve an initial phase with pretreatment, washing and rinsing the implants received, to ensure they are all equally clean, eliminating or minimising the presence of oils and grease coming from external mechanical processes.

After the initial wash, the first acid etching procedure is carried out on the implants. The part is then washed, which is followed by chemical pickling treatment and acid etching. Next step is the neutralisation process, washing and rinsing with water to eliminate chemical residue left behind by the pickling and etching process. After washing, the implants are dried and decontaminated with a plasma treatment.