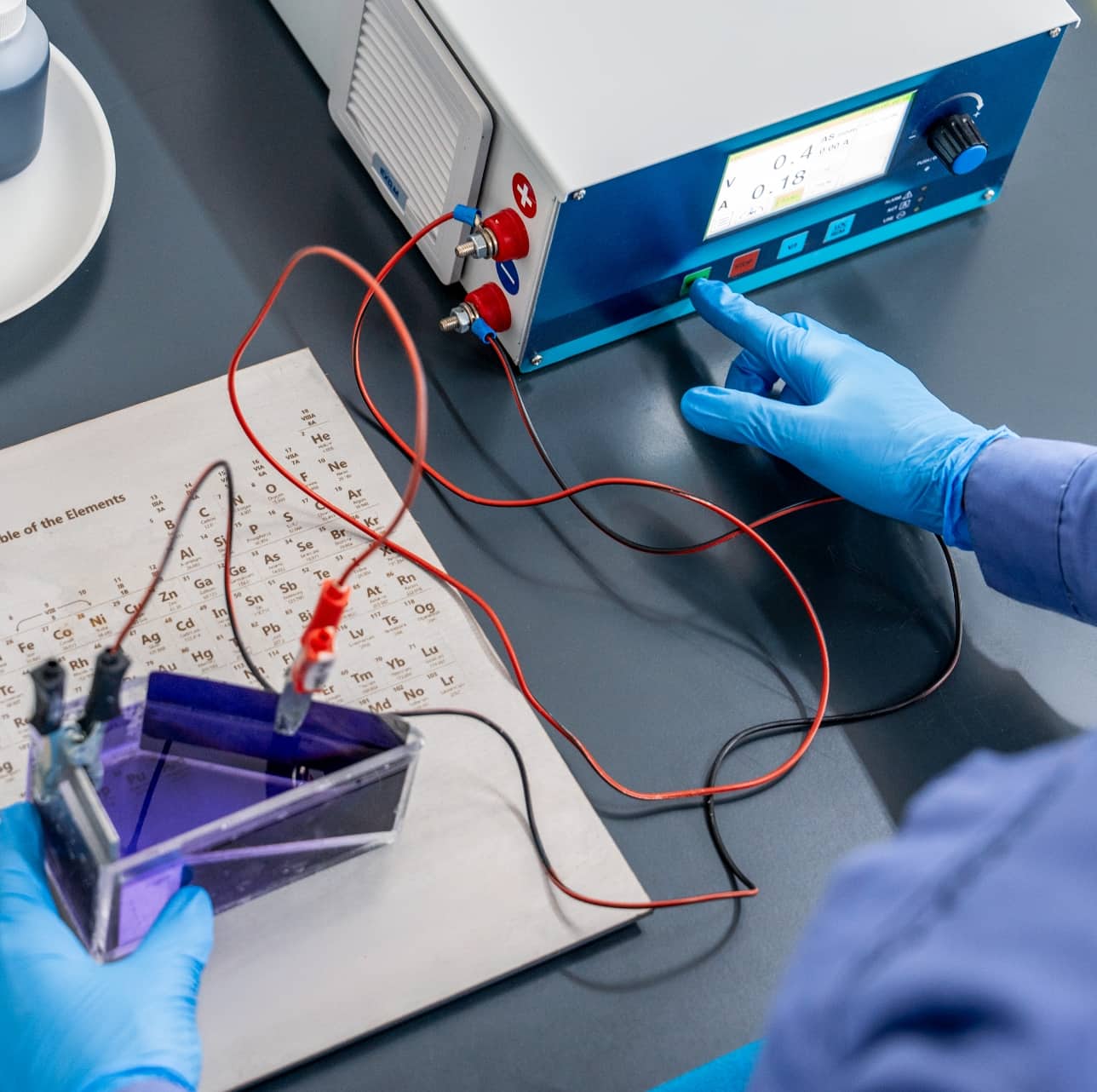

Preliminary analysis in the Hull cell

Alticolor employs the Hull Cell to evaluate the parameters of the galvanic bath prior to performing the zinc-nickel process. This tool analyzes the coating behavior in relation to current density, monitoring uniformity, thickness, and quality of the deposit. It also identifies the optimal composition of the galvanic solution, ensuring compliance with technical standards and maximum reliability of the treatment.